Picking the right motor for your radio-controlled airplane is a key step. The motor you choose directly influences how your plane flies, affecting its speed, climb rate, and overall handling. What should you look for when selecting one? Let's explore the options available for your RC aircraft.

RC Plane Motor Type Comparison

Brushed vs. Brushless Motors

You'll mainly encounter two types of electric motors in the RC plane world: brushed and brushless motors.

Brushed motors are an older design. They use small carbon blocks, called brushes, to physically contact the spinning part of the motor and deliver electricity. They are generally simpler and were common in entry-level models. However, these brushes wear down over time and need replacement. Brushed motors are also typically less efficient than their brushless counterparts, meaning more battery power is lost as heat.

Brushless motors represent a more modern technology and are widely used today. Instead of brushes, they use an electronic speed controller (ESC) to manage the flow of electricity to different parts of the motor, causing it to spin. Because there are no brushes to wear out, they generally last longer and require less maintenance. They are also more efficient, converting more electrical energy into rotational power. This efficiency often translates to more power for the same weight compared to a brushed motor, or longer flight times. Many ready-to-fly planes, including various foam trainers and sport models, come equipped with brushless systems.

Types of Brushless Motors: Outrunner vs. Inrunner

Within the brushless category, there are two main configurations:

- Outrunner: In an outrunner motor, the outer casing or "can" of the motor rotates around the stationary inner windings (stator). The propeller usually mounts directly to this spinning case. Outrunners typically have lower Kv ratings (we'll discuss Kv next) and produce more torque at lower speeds. This makes them well-suited for turning larger propellers directly, which is common in many types of RC planes, from trainers to scale models.

- Inrunner: An inrunner motor works the opposite way. The central shaft (rotor) spins inside a stationary outer casing. Inrunners generally have higher Kv ratings and spin much faster but produce less torque. They are often smaller in diameter but longer than outrunners of similar power. You might find them in very fast jets, often connected to a gearbox to reduce speed and increase torque, or inside electric ducted fans (EDFs).

For most propeller-driven RC planes, especially trainers, sport flyers, and gliders like those often seen from brands specializing in easy-to-fly models, brushless outrunner motors are a very common choice.

Understanding Motor Specifications: Kv Rating

When looking at brushless motors, one of the most important specifications you'll see is the Kv rating. This number indicates the motor's revolutions per minute (RPM) per volt applied to it, with no load (meaning no propeller attached).

For example, a motor rated at 1000Kv, when connected to a 3-cell LiPo battery (which provides about 11.1 volts), will try to spin at approximately 11,100 RPM (1000 Kv x 11.1V) without a propeller.

- Lower Kv Motors (e.g., 800Kv - 1200Kv): Spin slower for a given voltage. They are typically better at swinging larger, more efficient propellers and generate more thrust (pulling power) at lower speeds. Good for trainers, scale planes, and gliders.

- Higher Kv Motors (e.g., 1500Kv - 2500Kv+): Spin faster. They are usually paired with smaller propellers and are suited for faster sport planes, pylon racers, or jets.

The Kv rating itself doesn't directly tell you how powerful a motor is; power also depends on the voltage and the current (amperage) the motor draws. However, Kv gives you a crucial indication of the motor's speed characteristics.

Matching Components: Motor, ESC, Battery, and Propeller

Choosing a motor is only part of building the power system. You must ensure all components work together correctly:

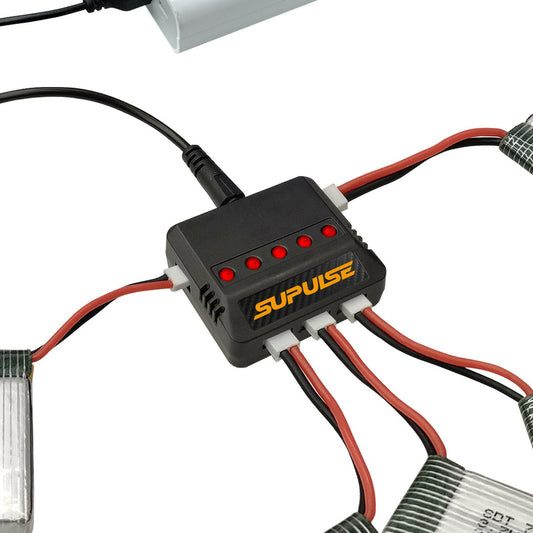

- ESC (Electronic Speed Controller): The ESC acts as the brain between your battery and brushless motor. It needs to be rated to handle both the voltage of your battery (e.g., 2S, 3S, 4S LiPo) and the maximum current (amps) your motor will draw under load with the chosen propeller. Using an undersized ESC can lead to overheating and failure.

- Battery: The battery voltage (measured in volts, often determined by the cell count 'S' for LiPo batteries) directly affects the motor's RPM (RPM ≈ Kv x Volts). The battery's capacity (mAh) affects flight time, and its C-rating affects its ability to deliver current.

- Propeller: The size (diameter) and pitch of the propeller have a huge impact on performance and how much current the motor draws. A larger diameter or higher pitch prop makes the motor work harder, drawing more current. You need to choose a propeller that provides the desired performance without overloading the motor or ESC.

Plane manufacturers, including those like VolantexRC who offer ready-to-fly or plug-and-play models, often provide recommendations for motor size, Kv rating, ESC, battery, and propeller combinations that work well for a specific airframe. Checking the manual or product description for your plane kit is usually a good starting point. What kind of flight experience are you hoping to achieve with your model? Considering this will help guide your motor selection.